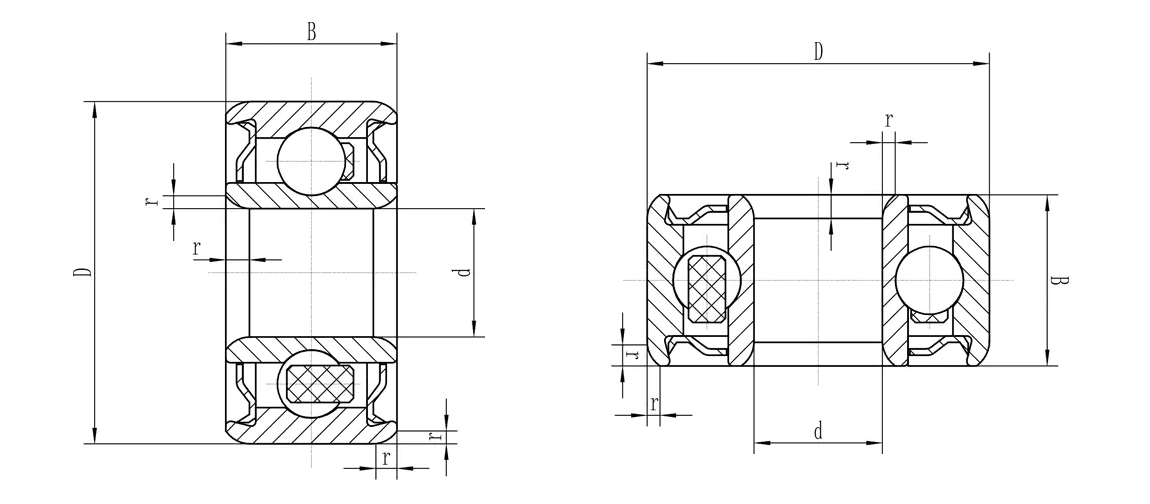

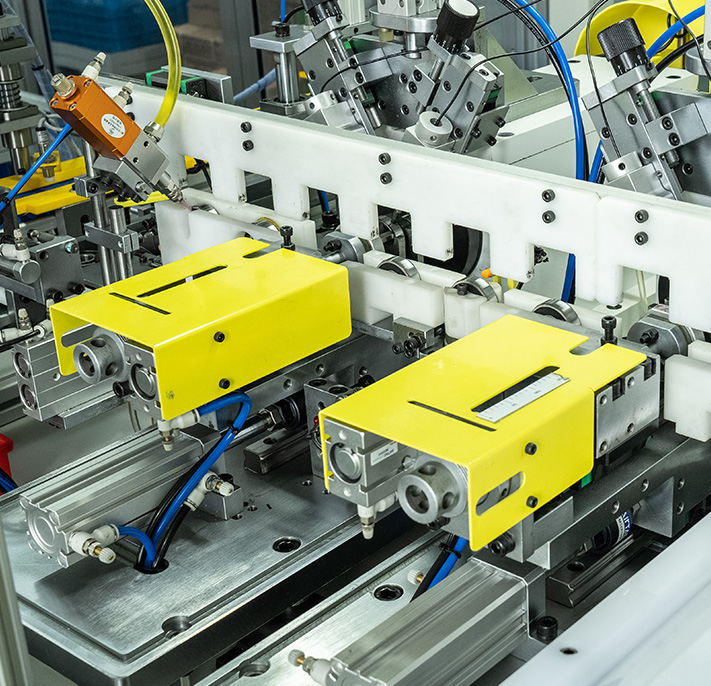

We are a bearing manufacturer integrating the research, development, and sales of bearings. We stick to the principle of quality first, service first" for the management, Equipped with a modern fully automatic production line, and advanced detection instruments, and have established a professional product laboratory to ensure the performance of products in various fields.

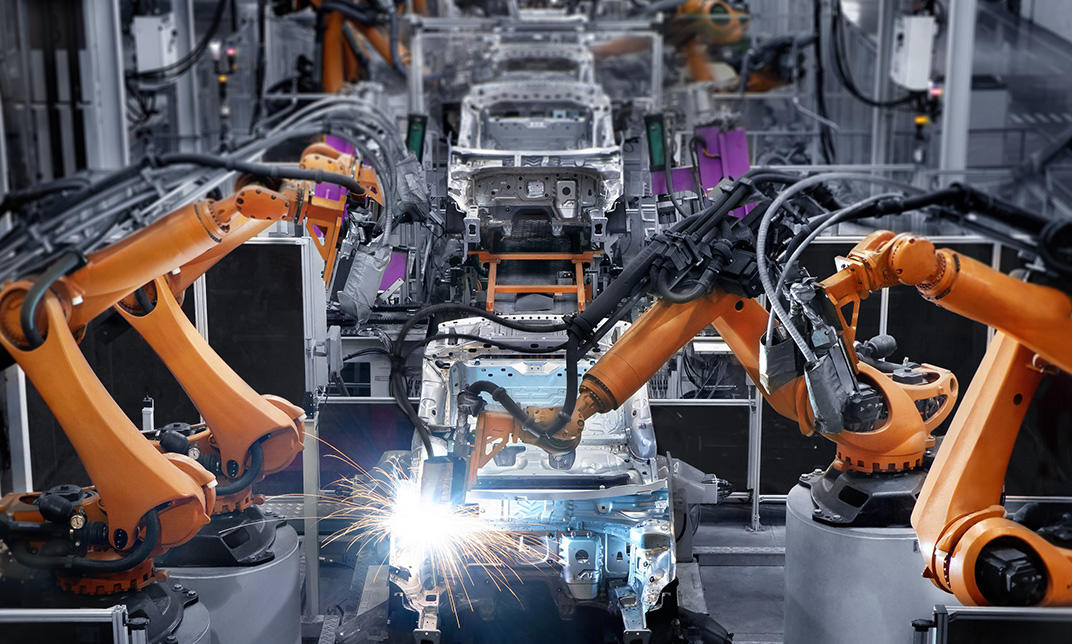

As professional OEM/ODM Deep groove ball bearing 63 series manufacturers and Deep groove ball bearing 63 series factory, Our bearings are widely used in complete products in engineering machinery, agricultural, and packing industries, in addition to various applications at airports, in air-conditioning systems, conveying devices, ships, and so on. Especially in the field of RO pumps, The company has been working in professional research and development of water pump bearings for more than ten years since 2009. Over the past 10 years, we have continuously improved and designed special pump bearings for pumps according to all customer's requirements, which greatly improved the overall quality of the pumps and was well received by customers.

English

English 中文简体

中文简体 عربى

عربى Español

Español